PepsiCo: High-Capacity DG Compliance

PepsiCo

Who

Dec-Jan 2025

When

Pune

Where

Project Overview

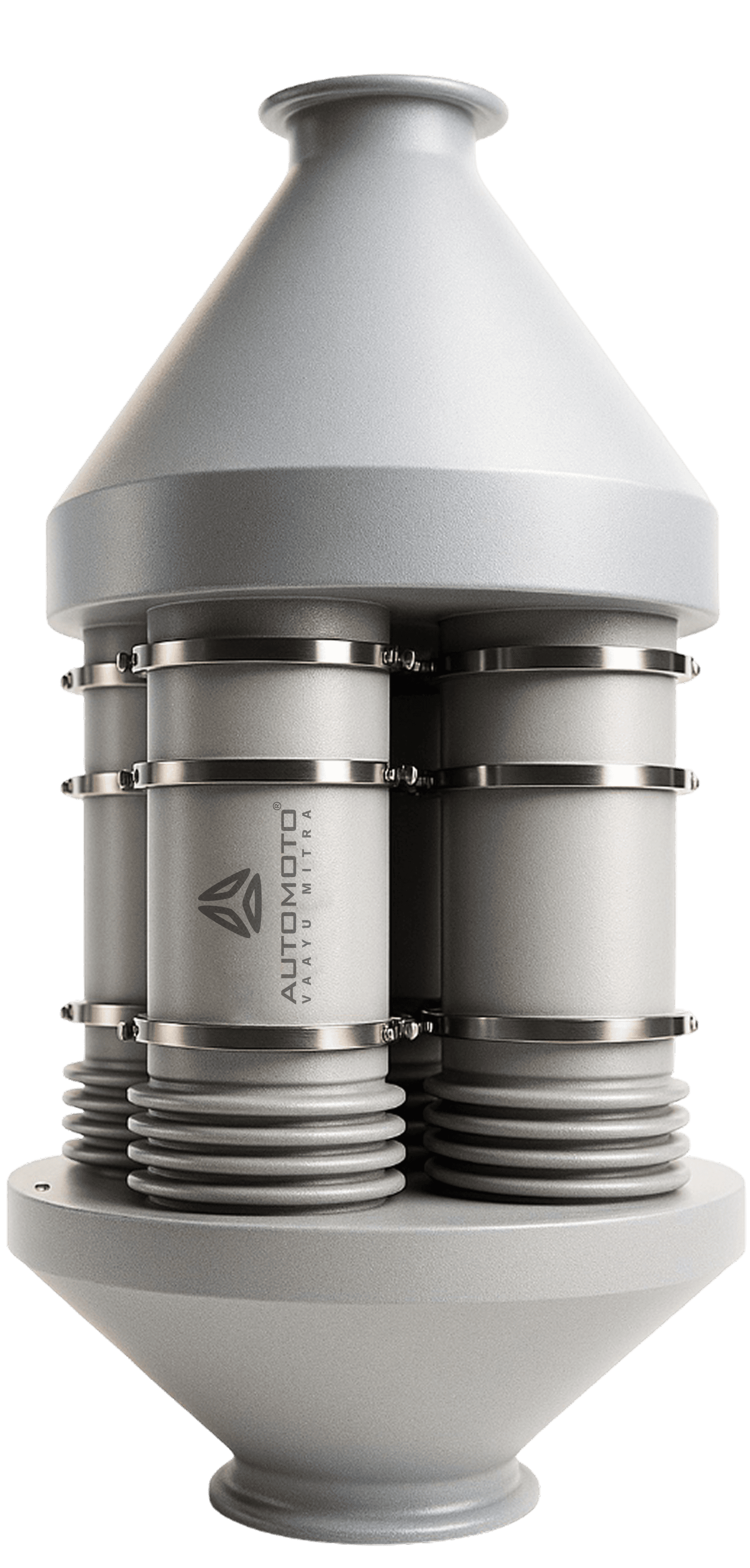

Automoto executed a high-capacity RECD deployment for PepsiCo at its Pune facility to ensure emission compliance for large diesel generator systems supporting critical manufacturing and operational processes. The project was planned to integrate emission control without impacting plant productivity or power reliability.

Geographical Footprint

Pune (Maharashtra)

Project Timeline

December – January

Deployment Scale

Total RECD Units Installed: 3

RECD Capacity Range: 1010 kVA – 2000 kVA

Compliance & Operational Impact

The deployment enabled the facility to meet CPCB and state pollution control board requirements applicable to large-capacity DG operations. By proactively upgrading emission control systems, the client reduced regulatory exposure during inspections and compliance audits, mitigating the risk of penalties, notices, or operational disruptions—particularly critical for high-output industrial power infrastructure.

The implementation also strengthened long-term compliance assurance by standardizing emission control across all high-capacity backup systems.

Environmental & Sustainability Benefits

By controlling emissions from very high-capacity DG sets, the project significantly reduced particulate matter and exhaust emissions within the industrial zone. This contributed to improved ambient air quality while aligning the client’s operations with broader sustainability and environmental responsibility goals.

Outcome

This case study demonstrates Automoto’s expertise in delivering very high-capacity RECD solutions for industrial manufacturing environments, combining compliance, environmental impact mitigation, and operational continuity at scale.