Berger Paints: Multi-State RECD Compliance

Berger Paints

Who

Sep-Oct 2025

When

Pan India

Where

Project Overview

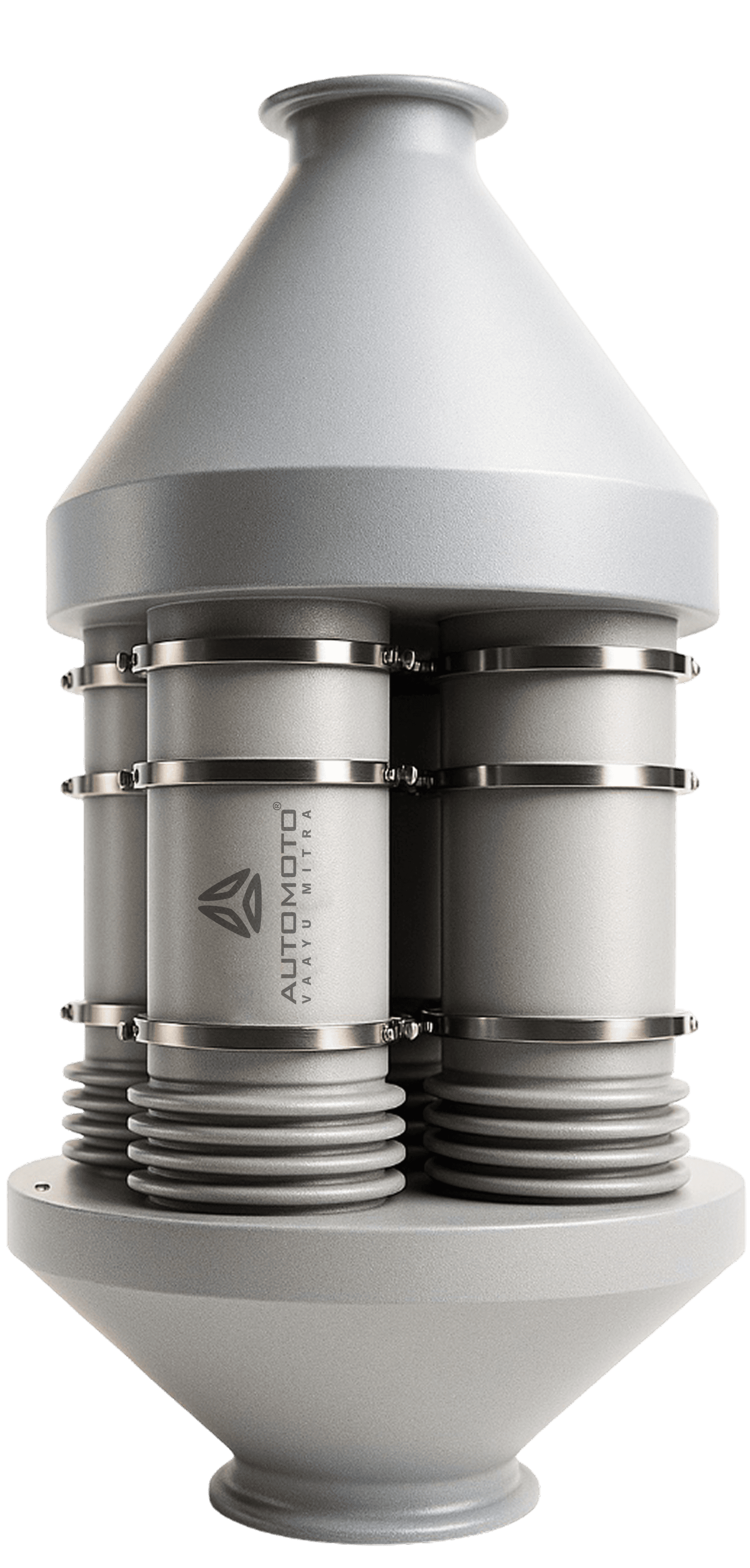

Automoto executed a multi-state RECD deployment for Berger Paints India to ensure emission compliance across manufacturing and operational facilities operating large-capacity diesel generator sets. The project was planned to accommodate varied regional regulations while maintaining uninterrupted plant operations.

Geographical Footprint

Gujarat

Jammu & Kashmir

Goa

Maharashtra

Project Timeline

September – October

Deployment Scale

Total RECD Units Installed: 10

RECD Capacity Range: 250 kVA – 1500 kVA

Compliance & Operational Impact

The deployment enabled Berger Paints to align DG set operations with CPCB and respective state pollution control board norms across multiple regulatory environments. By proactively implementing compliant emission control systems, the client reduced exposure to inspection-related risks, penalties, and potential operational interruptions—particularly important for facilities operating high-capacity backup power systems.

The standardized RECD implementation also simplified compliance monitoring across sites and ensured consistent emission performance regardless of location or DG capacity.

Environmental & Sustainability Benefits

By controlling emissions from high-capacity DG sets, the project contributed to reduced particulate matter and exhaust pollution across industrial regions and surrounding communities. This supported cleaner air quality while reinforcing the client’s commitment to environmentally responsible manufacturing practices.

Outcome

This case study highlights Automoto’s strength in delivering multi-state, large-capacity RECD implementations—combining compliance assurance, environmental impact reduction, and execution consistency for enterprise manufacturing clients.