Sun Pharma: High-Capacity RECD Compliance

Sun Pharma

Who

November

When

Tamil Nadu

Where

Project Overview

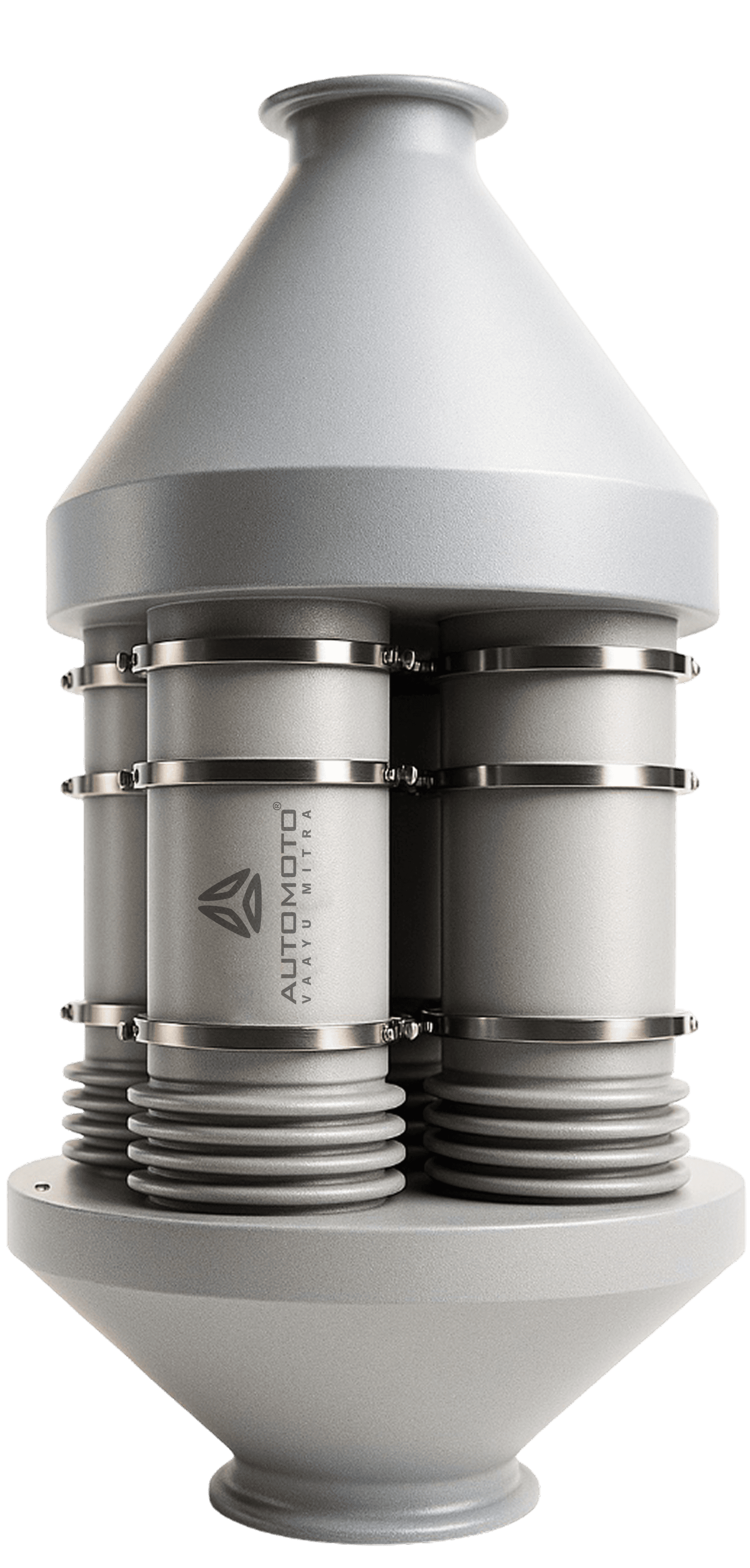

Automoto executed a high-capacity RECD deployment for Sun Pharmaceutical Industries at its Tamil Nadu facility to ensure emission compliance for mission-critical diesel generator systems. Given the continuous and regulated nature of pharmaceutical operations, the project was designed to integrate emission control without affecting production stability or power reliability.

Geographical Footprint

Tamil Nadu

Chennai

Project Timeline

November

Deployment Scale

RECD Units Installed: 3 (High-capacity configurations)

RECD Capacity Range: 500 kVA – 1500 kVA

Compliance & Operational Impact

The deployment enabled the facility to align large-capacity DG operations with CPCB and state pollution control board requirements applicable to pharmaceutical manufacturing units. By proactively implementing compliant emission control systems, the client reduced exposure to regulatory non-compliance, inspection risks, and potential operational disruptions—critical in a sector governed by stringent environmental and operational standards.

The installation also strengthened audit readiness by ensuring emission control consistency across all high-output backup power systems.

Environmental & Sustainability Benefits

By controlling emissions from very high-capacity DG sets, the project significantly reduced particulate matter and exhaust emissions in and around the industrial zone. This contributed to improved ambient air quality while supporting the client’s broader sustainability and environmental stewardship objectives.

Outcome

This case study underscores Automoto’s capability to deliver high-capacity RECD solutions for regulated industries, combining compliance assurance, environmental impact reduction, and operational continuity for pharmaceutical manufacturing environments.