Introduction

In the industrial world, diesel generator (DG) sets are lifelines for uninterrupted power. However, with rising environmental concerns and increasingly strict government regulations, DG sets have become a double-edged sword. Escalating air pollution levels in industrial zones have pushed policymakers and businesses alike to act quickly—and responsibly.

Enter RECD (Retrofit Emission Control Devices)—a government-approved solution transforming how industries manage diesel emissions. In this blog, we break down the key benefits of installing RECD kits on industrial DG sets, answer common questions, and explain how this investment delivers long-term returns in compliance, cost savings, and corporate credibility.

What Is an RECD Kit and Why Should You Care?

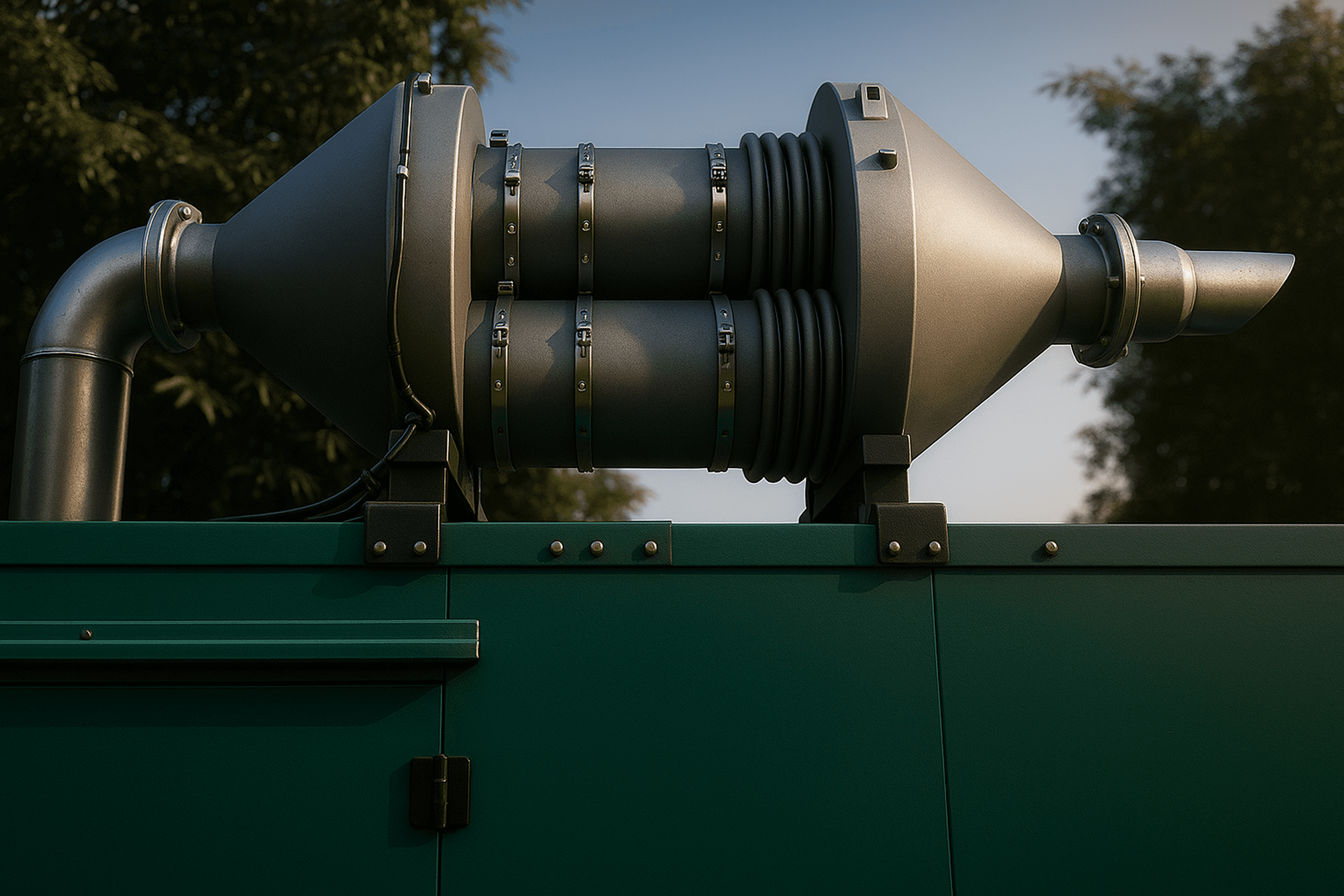

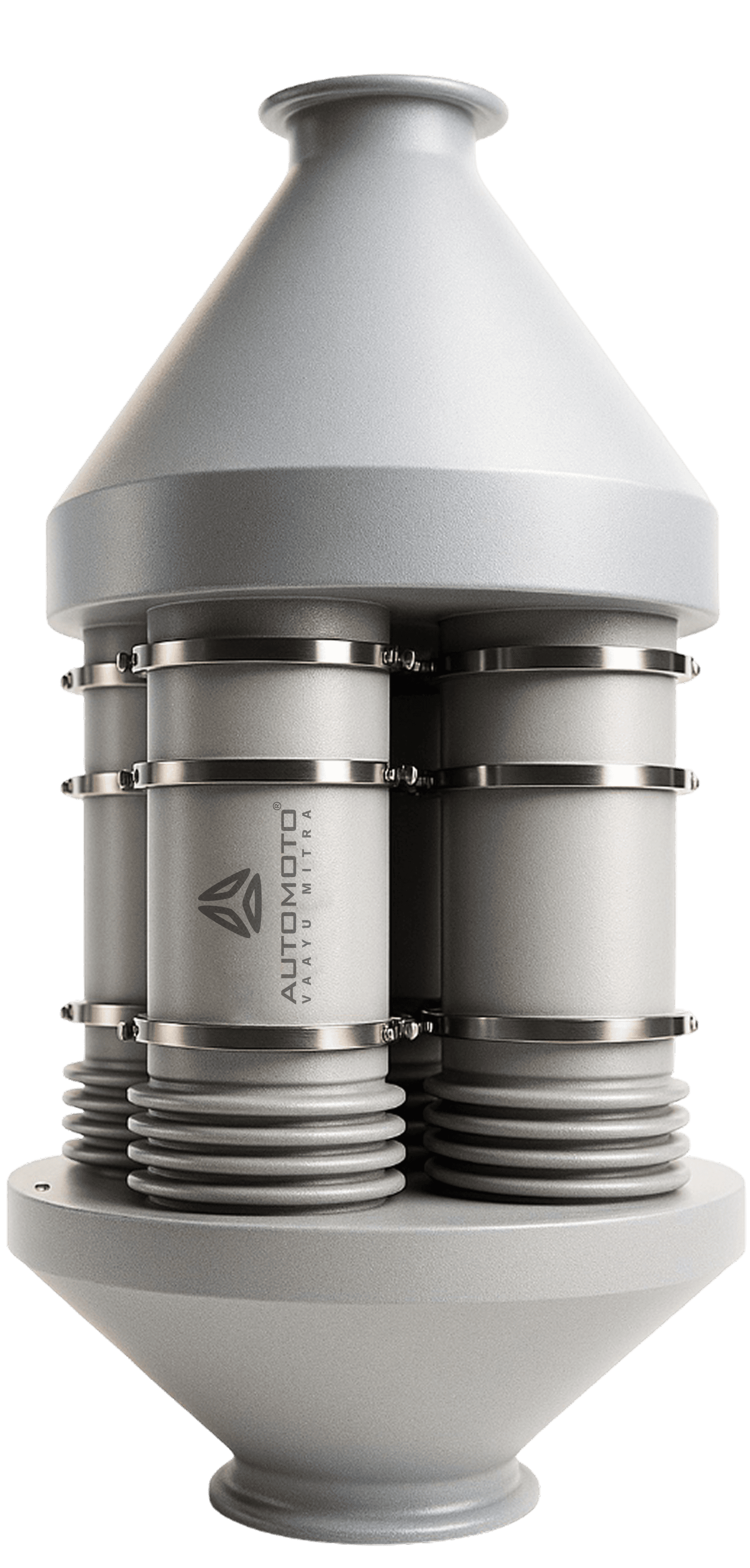

A Retrofit Emission Control Device (RECD) is an exhaust-mounted filtration and after-treatment system designed to reduce harmful pollutants such as particulate matter (PM), hydrocarbons (HC), and carbon monoxide (CO), without compromising generator performance.

In India, the Central Pollution Control Board (CPCB) mandates the installation of RECD kits for DG sets ranging from 40 kVA to 1000 kVA, particularly in high-pollution and non-attainment zones such as Delhi NCR.

For industrial operators, non-compliance can result in shutdown notices, legal penalties, and long-term brand damage.

Key Benefits of Installing RECD Kits in Industrial DG Sets

1. Instant CPCB Compliance

RECD kits help industries align with CPCB Phase II emission norms. With enforcement tightening, certified RECD installations ensure DG sets remain legally operational and audit-ready.

2. Significant Emission Reduction

Modern RECD systems have demonstrated particulate matter reduction of up to 99.21% under ICAT testing conditions, directly improving air quality within and around industrial premises.

3. Reduced Regulatory Risk and Penalties

By maintaining compliant emission levels, industries significantly lower the risk of penalties, notices, and enforced shutdowns issued by pollution control authorities.

4. Maintains Generator Efficiency

RECD systems are engineered to preserve DG performance, ensuring no loss of power output or fuel efficiency while maintaining stable exhaust back pressure.

5. Ensures Business Continuity

In regions with strict enforcement, non-compliant DG sets are frequently restricted during high-pollution periods. RECD installation enables uninterrupted operations during such regulatory interventions.

6. Improves ESG Performance

Environmental, Social, and Governance (ESG) metrics increasingly influence investor and stakeholder decisions. RECD deployment demonstrates measurable commitment to emission reduction and sustainable operations.

7. Strengthens Brand Reputation

Adopting certified emission control solutions reinforces an organisation’s image as environmentally responsible and regulation-compliant—an advantage in B2B, export, and institutional markets.

8. Enables Access to Government Projects

Many public-sector tenders and infrastructure projects require proof of environmental compliance. RECD-equipped DG sets improve eligibility for government contracts and competitive bids.

9. Low Maintenance with Long-Term ROI

RECD kits are designed for durability and low upkeep. Long-term returns are driven by avoided penalties, reduced legal exposure, and uninterrupted operational continuity.

Frequently Asked Questions (FAQs)

Is RECD installation mandatory for all DG sets?

CPCB mandates RECD installation primarily for DG sets between 40 kVA and 1000 kVA. However, voluntary adoption beyond this range can still provide compliance and operational advantages.

Does RECD affect fuel consumption?

Certified RECD systems are designed to maintain optimal exhaust flow and combustion parameters, resulting in no significant increase in fuel consumption.

How much does an RECD kit cost?

Pricing varies by capacity and configuration. Costs typically start from approximately ₹1,25,000 for smaller DG sets and increase with higher capacities and technical specifications.

Can RECD be installed on older DG sets?

RECD systems are retrofittable and can be installed on older or imported DG sets with minor exhaust modifications.

Are all RECD kits CPCB-approved?

Only CPCB-approved RECD kits are compliant. Always ensure the vendor provides valid approval numbers and certification documentation.

Real Impact: Industrial Compliance in Action

A plastics manufacturing unit in Faridabad faced repeated notices from the Pollution Control Board for operating a 250 kVA DG set. After installing a CPCB-certified RECD kit, the unit resumed uninterrupted operations and achieved an eco-compliance certification—helping it strengthen its position in export and institutional supply chains.

Conclusion

In today’s regulation-driven industrial environment, RECD kits are no longer optional—they are essential. They bridge the gap between operational reliability and environmental responsibility. From reducing emissions and regulatory exposure to safeguarding business continuity and market credibility, RECD installation is a future-ready investment.

Proactive compliance today prevents enforced action tomorrow. Installing RECD solutions positions industries for cleaner operations, uninterrupted growth, and long-term regulatory confidence.