What is RECD (Retrofit Emission Control Device)

RECD (Retrofit Emission Control Device) is a pollution control technology installed on the exhaust system of diesel generator sets to reduce harmful emissions such as particulate matter (PM), hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx).

Definition

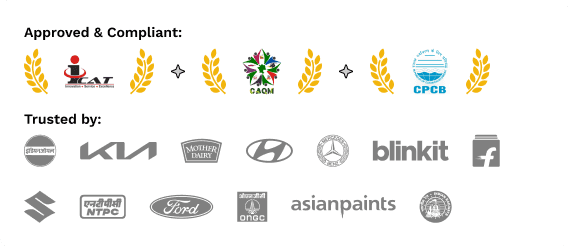

A CPCB-approved And ICAT- Tasted RECD is a retrofitted after-treatment device that brings non-compliant diesel generators into conformity with prescribed air quality standards.

Key Characteristics

No engine modifications required

Plug-and-play installation

Low maintenance operation

Mandatory under CPCB & CAQM norms

Why Emission Control Matters in Today’s World

In a world facing rising air pollution and increasingly strict emission regulations, diesel generator (DG) set operators are under growing pressure to comply with eco-friendly norms. RECD—Retrofit Emission Control Devices—offer a CPCB-certified solution designed to control diesel emissions directly at the source.

Whether you are a factory owner, real estate developer, facility manager, or energy consultant, understanding RECD can be a critical step toward long-term compliance and sustainable operations.

In this guide, we break down what RECD is, how it works, why it matters, and how it aligns with India’s evolving emissions roadmap.

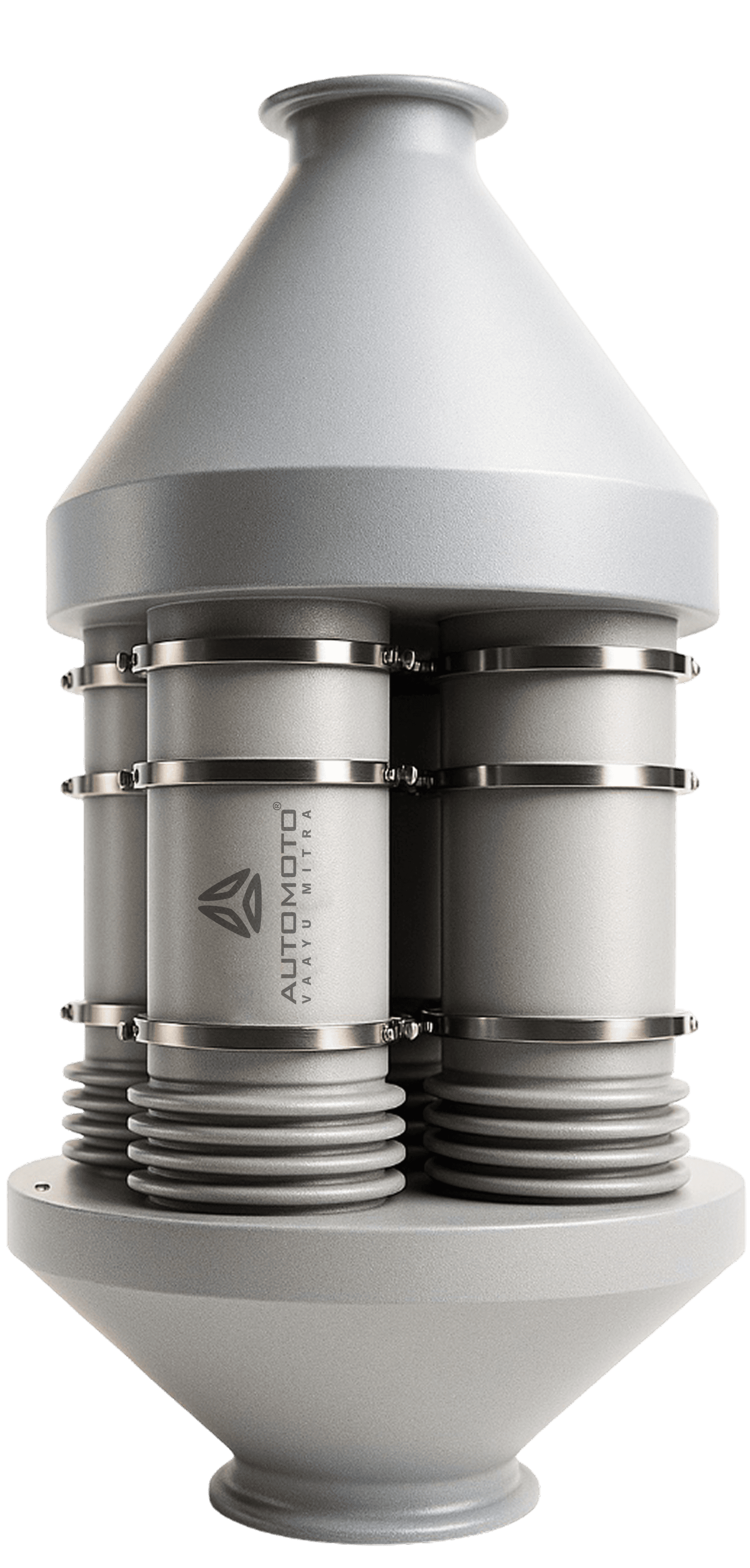

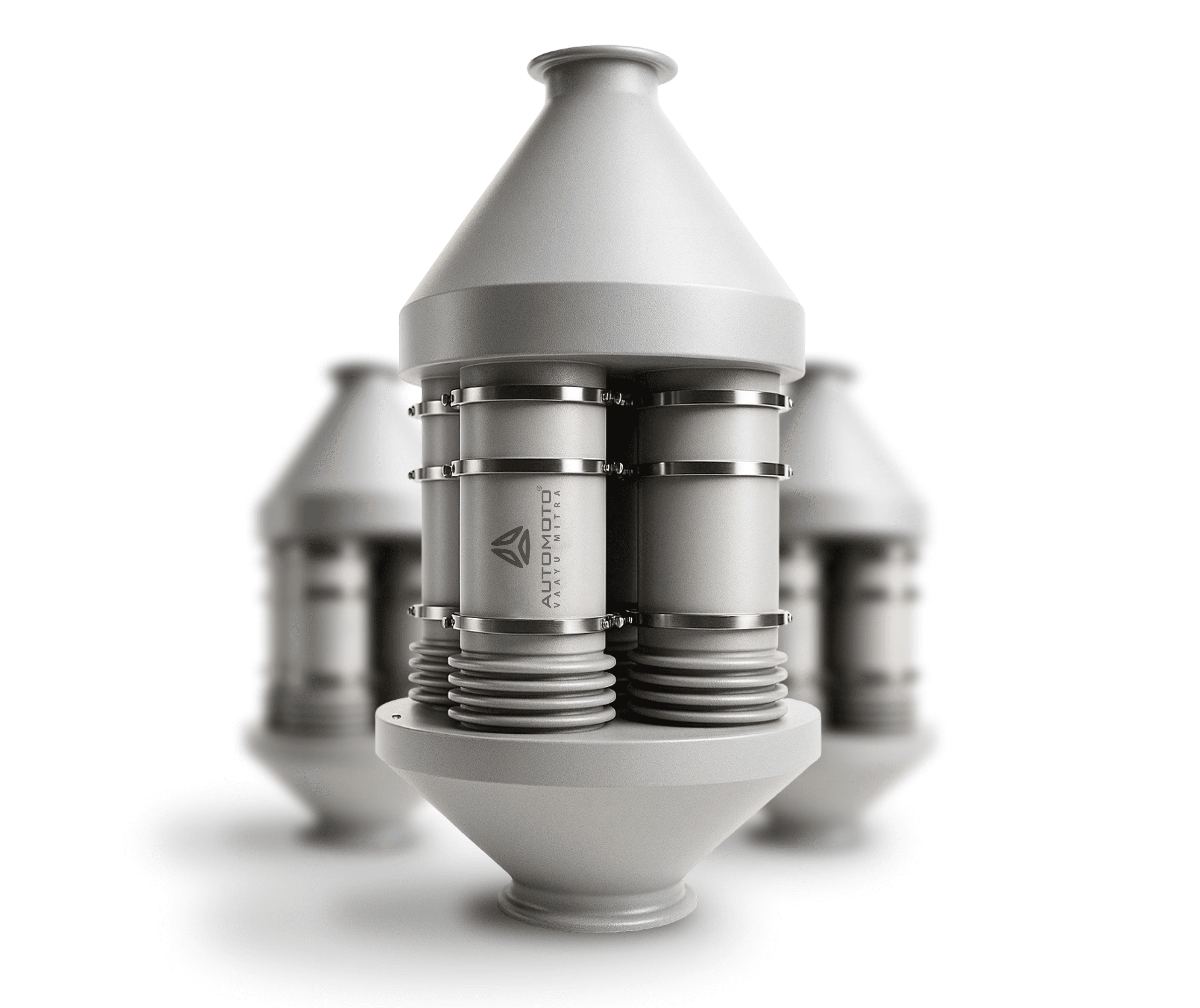

How Does Our RECD Work?

RECD systems are mounted on the DG set exhaust outlet and operate using a two-stage filtration mechanism.

Stage 1: Catalytic Converter

Oxidises harmful exhaust gases by converting hydrocarbons and carbon monoxide into carbon dioxide (CO₂) and water (H₂O).

Stage 2: Diesel Particulate Filter (DPF)

Captures and burns off particulate matter (PM) emitted from DG sets using a ceramic honeycomb structure.

These stages work together to trap and neutralise pollutants before they are released into the atmosphere.

RECD vs Traditional DPF - What's Better?

Feature | Automoto RECD | Standard DPF |

|---|---|---|

Emission Reduction | 99.21% | 85-90% |

Engine Modification | Not Required | Sometimes Required |

Fuel Consumption | Zero Extra | 2-3% Extra |

Regeneration | Automatic | Manual Active |

CPCB Approval | Ranges - 15kW to 800 kW | Limited |

Maintenance | Low | Medium |

Installation | 4-6 hours | 8-12 hours |

What's Included in RECD Cost?

CPCB-approved RECD device with catalytic converter and DPF

Professional installation by certified technicians

Control panel and monitoring system

Initial calibration and emission testing

12-month standard warranty

Technical documentation and compliance certificates

Why 3000+ Industries Trust Automoto Vaayu Mitra®?

ICAT Tested & CPCB Approved:

Helps avoid shutdowns, penalties, and regulatory actions under CPCB and National Green Tribunal (NGT) norms.

Reduced Air Pollution

Achieved up to 99.21% reduction in particulate matter emissions during ICAT testing.

Zero Fuel Consumption

No additional fuel is used for RECD regeneration.

Wide Industry Compatibility

Suitable for DG sets ranging from 15 kVA to 1000+ kVA.

Smart Monitoring

IoT-enabled control panels for real-time emission tracking.

Supports ESG and Sustainability Goals

Helps organisations meet environmental, sustainability, and CSR commitments.

Improved Public and Regulatory Perception

Positions organisations as responsible, compliant, and environmentally conscious.

Who Needs an RECD? Key Industries Benefiting the Most

Real Estate Developers

Industrial Plants and Manufacturing Facilities

Hospitals and Healthcare Institutions

Shopping Malls and Commercial Complexes

Warehouses and Data Centers

Construction Sites

Educational Institutions

RECD solutions are especially relevant for urban and semi-urban areas with active air quality monitoring and stricter enforcement.

Return on Investment (ROI)

While the upfront investment may seem significant, RECD helps you avoid:

CPCB penalties ranging from ₹1-5 lakhs

Operational shutdown costs (₹50,000+ per day in lost productivity)

Environmental compliance violations and legal notices

Damage to corporate reputation and ESG ratings

Frequently Asked Questions

Is RECD mandatory?

Yes. CPCB mandates emission control solutions for diesel generator sets to meet prescribed emission norms.

How long does an RECD last?

With proper operation and maintenance, RECD systems typically last more than 10 years.

What is the particulate capture capacity of Automoto RECD?

Automoto RECD systems are capable of capturing more than 90% of particulate matter emitted by the engine.

What is the price of RECD in India?

Based on DG set capacity. A 125 kVA generator costs around ₹1,50,000-₹2,00,000, including installation. Contact Automoto for exact pricing.

How long does RECD installation take?

Standard diesel RECD installation takes 4-6 hours. Mounting, connecting, calibrating, and testing are included. It's plug-and-play, needs no engine mods, and is done in a day.

Is RECD mandatory under CAQM rules?

CAQM Direction 71 requires NCR diesel generators to install CPCB-approved emission control devices like RECD to avoid penalties, restrictions, or shutdown. RECD ensures emission compliance

Which is the best RECD brand in India?

Automoto Vaayu Mitra®: India's top ICAT-tested, CAQM-approved RECD. 3000+ installed. Choose RECD based on CPCB approval, ICAT certification, 99.21%+ emission reduction, warranty, support, and DG set compatibility.