Retrofit Emission Control Devices (RECD) for DG Sets

Diesel Generator (DG) sets play a critical role in providing backup power to industries, commercial establishments, and residential complexes. From hospitals to manufacturing plants, DG sets ensure uninterrupted operations during power outages. However, despite their importance, DG sets are also a significant source of air pollution.

They emit harmful pollutants such as nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC). To address these environmental challenges, Retrofit Emission Control Devices (RECD) have emerged as an effective solution for reducing emissions and supporting cleaner, more sustainable operations.

Why Emission Control for DG Sets Is Essential

As air quality concerns intensify and governments worldwide enforce stricter emission norms, industries are under increasing pressure to reduce pollution from diesel-powered equipment. Retrofitting existing DG sets with emission control solutions offers a practical and cost-effective alternative to replacing generators entirely.

RECD technology enables businesses to significantly lower emissions from existing assets while meeting regulatory requirements and contributing to improved air quality.

What Is a Retrofit Emission Control Device (RECD)?

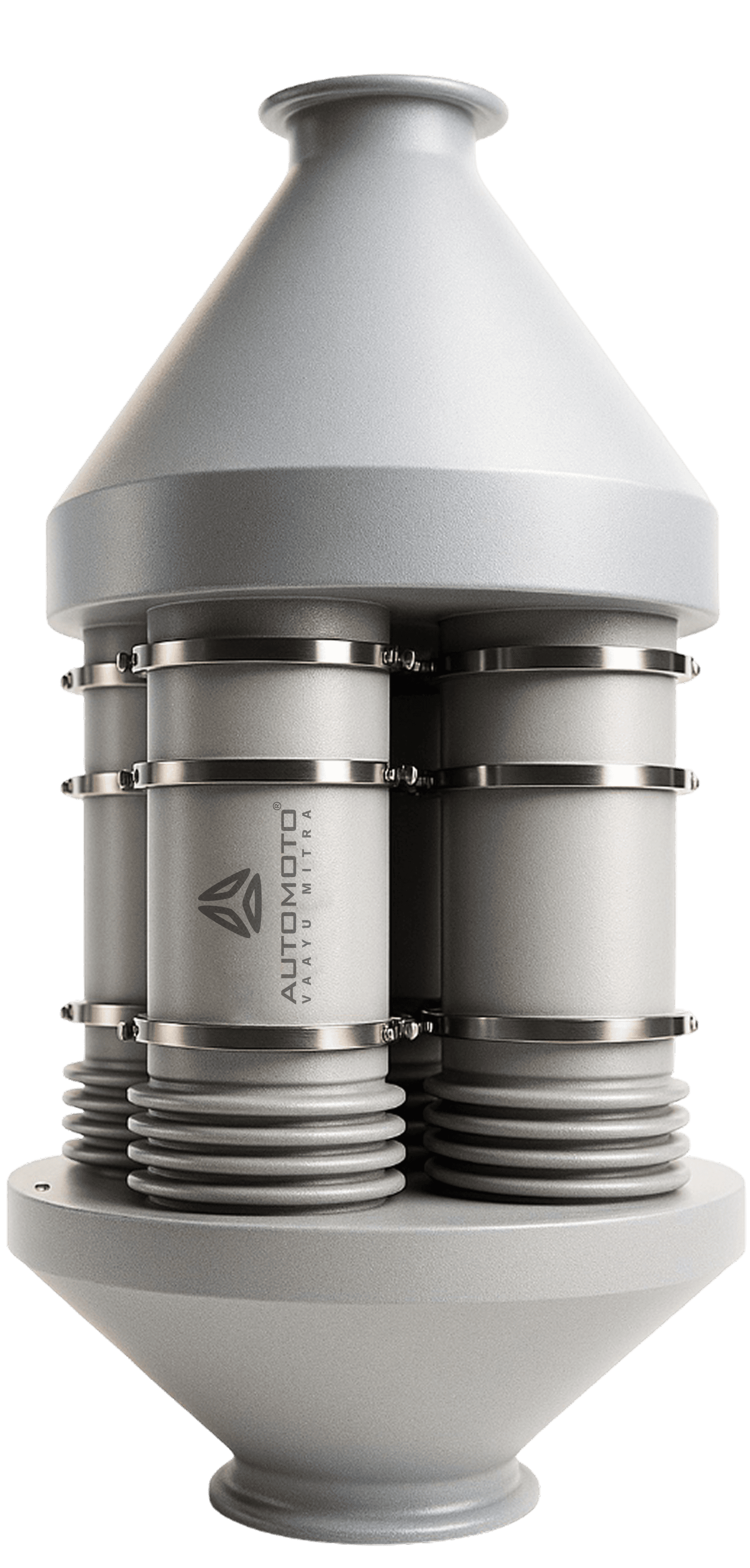

A Retrofit Emission Control Device (RECD) is an advanced emission control system designed specifically for diesel generator sets. It is installed within the exhaust system of an existing DG set and works to filter, convert, and neutralise harmful pollutants before they are released into the atmosphere.

Unlike replacing a generator with a newer low-emission model, an RECD allows businesses to continue using their current DG sets while achieving compliance with increasingly stringent emission standards. This makes RECDs a practical, affordable, and scalable solution—especially in regions such as India, where emission regulations are tightening rapidly.

One of the key advantages of RECD technology is that it delivers substantial emission reduction without compromising DG set performance or reliability.

How Does RECD Work?

RECD systems operate using a combination of filtration and catalytic processes designed to minimise harmful exhaust emissions.

Particulate Filters

Particulate filters capture and trap fine particulate matter such as soot and ash generated during diesel combustion. These particles are a major contributor to respiratory illnesses and degraded air quality. By preventing their release, RECD systems help protect both human health and the environment.

Oxidation Catalysts

Oxidation catalysts convert harmful carbon monoxide (CO) and unburnt hydrocarbons (HC) into less harmful substances such as carbon dioxide (CO₂) and water vapour. This process reduces toxic emissions while maintaining efficient exhaust flow.

Selective Catalytic Reduction (SCR)

Selective Catalytic Reduction systems target nitrogen oxides (NOx), which contribute to smog and acid rain. SCR technology introduces a reagent, typically urea or ammonia, into the exhaust stream, where it reacts with NOx in the presence of a catalyst and converts it into harmless nitrogen and water vapour.

By integrating these technologies, RECD systems can reduce harmful emissions by up to 90 percent, allowing DG sets to meet stringent environmental standards without requiring major modifications or replacements.

Leading the Way with RECD Technology

At Automoto Genset Solutions, we specialise in delivering high-performance RECD solutions designed to meet the most demanding emission control requirements. Our RECD systems are tested and approved by recognised authorities, including ICAT, CPCB, and CAQM, ensuring compliance with current regulatory frameworks.

Our engineering team works closely with clients to assess operational requirements and recommend RECD solutions compatible with a wide range of DG capacities—from small commercial installations to large industrial generators. Each solution is designed to balance compliance, performance, and long-term reliability.

Join the Movement for Cleaner Air

By installing Automoto’s RECD solutions on your DG sets, you take a meaningful step toward reducing emissions and improving air quality. Beyond regulatory compliance, RECD adoption supports healthier communities, more sustainable operations, and long-term environmental responsibility.

Cleaner power today leads to a cleaner future for everyone.

Frequently Asked Questions

What is a Retrofit Emission Control Device (RECD)?

An RECD is a device designed to reduce harmful emissions from diesel generator sets by controlling pollutants such as particulate matter, nitrogen oxides, hydrocarbons, and carbon monoxide.

Why should I install an RECD on my DG set?

Installing an RECD helps meet emission regulations, reduces environmental impact, and improves overall exhaust quality while maintaining generator performance.

What approvals does Automoto’s RECD have?

Automoto’s RECD solutions are approved by ICAT, CPCB, and CAQM, ensuring compliance with applicable emission standards and regulatory requirements.

Is RECD compatible with all DG sets?

Automoto’s RECD systems are designed to be compatible with a wide range of DG set capacities and configurations, subject to technical assessment.

How can I get an RECD solution for my DG set?

An RECD solution can be selected based on DG capacity, application, and regulatory requirements, with technical guidance provided during evaluation.